Optimizing Your Spray Booth for Efficiency and Safety: A Comprehensive Guide

By:Admin

Introduction:

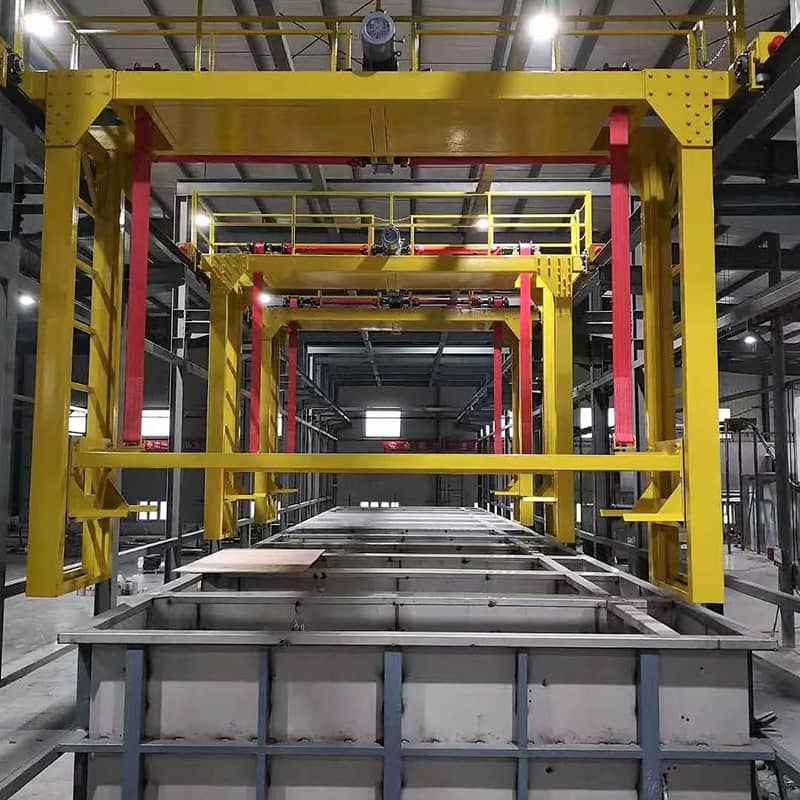

With an unwavering commitment to quality and innovation, renowned global manufacturer {} is proud to introduce its latest addition to its impressive lineup of industrial solutions – the highly efficient Standard Spray Booth. This state-of-the-art booth is designed to revolutionize the painting process across industries, ensuring superior quality, safety, and unparalleled performance.

Cutting-Edge Features:

The Standard Spray Booth boasts an array of cutting-edge features that set it apart from its competitors. Primarily, its advanced air filtration system utilizes high-efficiency filters to extract contaminants, dust, and overspray effectively, providing a clean and safe working environment while minimizing the risk of damage to finished products. This innovative system enhances productivity while adhering to strict environmental regulations.

Additionally, the booth integrates high-powered ventilation systems that maintain optimal airflow and circulation throughout the booth. This ensures consistent temperature control and efficient removal of fumes and odors, promoting worker safety and overall well-being.

Durability and Quality:

Built with precision and durability in mind, the Standard Spray Booth is constructed using high-quality materials that withstand the demands of industrial painting. Its robust structure is designed to provide stability while minimizing vibrations during operation, resulting in flawless finishes on all painted surfaces.

Furthermore, the booth incorporates cutting-edge LED lighting technology that guarantees uniform illumination, ensuring no shadowing or uneven coverage. This innovative lighting system improves visibility and color accuracy, enabling painters to achieve impeccable results every time.

Versatility and Customization:

Recognizing that every industry has unique requirements, the Standard Spray Booth offers exceptional versatility and customization options. This enables businesses to tailor the booth to their specific needs, ensuring seamless integration into their existing operations. From different sizes and airflow capacities to various booth designs, customers can choose the configuration that perfectly aligns with their workflow and productivity goals.

Moreover, the Standard Spray Booth can be equipped with optional extras such as personnel doors, windows, temperature control systems, and conveyor systems, further enhancing its adaptability to diverse industrial settings. This flexibility guarantees a tailored solution that maximizes efficiency and minimizes downtime.

Safety and Compliance:

The safety of workers and compliance with stringent regulations remain paramount considerations in any industrial setting. The Standard Spray Booth addresses these concerns with its state-of-the-art safety features. The booth incorporates a range of safety controls, including fire suppression systems, spark-proof fan blades, and explosion-proof lighting, ensuring a secure working environment.

Furthermore, the booth is designed in adherence to relevant industry standards, with certifications from recognized organizations, demonstrating its compliance with rigorous safety and quality requirements.

Improved Efficiency and Reduced Environmental Impact:

Recognizing the importance of both productivity and sustainability, the Standard Spray Booth optimizes resource utilization without compromising performance. This best-in-class booth reduces overspray and consumption of coatings, minimizing material waste and resulting in significant cost savings over time.

Moreover, its efficient filtration systems effectively capture harmful substances, reducing emissions and contributing to a healthier work environment. By minimizing the environmental impact of painting processes, businesses utilizing the Standard Spray Booth actively participate in promoting sustainable practices.

Conclusion:

The introduction of the Standard Spray Booth by {} marks a significant milestone in the field of industrial painting. Combining cutting-edge features, versatility, and unwavering commitment to safety and quality, this innovative booth sets a new standard for spray booth technology. With its exceptional performance, durability, and customizable features, businesses across various industries can now revolutionize their painting processes while prioritizing the well-being of their workers and the environment.

Company News & Blog

Enhance Your Wheels with a High-Quality Powder Coating Oven

[Headline]Cutting-Edge Oven for Powder Coating Wheels Revolutionizes Automotive Industry[Sub-heading]Innovative Solution Sets New Standard in Wheel Powder Coating, Promising Unparalleled Performance and Efficiency[Date][City, State][News]The automotive industry continues to witness groundbreaking innovations aimed at enhancing both aesthetics and performance. One such breakthrough comes in the form of an advanced oven specially designed for powder coating wheels. This cutting-edge technology, developed by a leading industry player, is set to revolutionize the way wheel manufacturing and refinishing is conducted, affirming the company's commitment to delivering unparalleled quality and efficiency to its customers.[Town, State] based company, renowned for its expertise and innovative solutions in wheel manufacturing, brings to the market a state-of-the-art oven that significantly enhances the wheel powder coating process. The oven, whose brand name must be omitted, has been meticulously developed by a team of engineers and designers with years of experience in the automotive industry.With a capacity to accommodate multiple wheels simultaneously, this industry-leading oven promises to boost production efficiency without compromising on product quality. The oven's design optimizes curing conditions by utilizing an unconventional arrangement of heating elements and advanced programming algorithms. Operated through a user-friendly interface, this advanced device allows for precise temperature and duration control, ensuring even powder coating distribution and outstanding curing results.The [company] understands that wheel manufacturers and refinishing businesses face the constant challenge of reducing turnaround time while maintaining the highest quality standards. To address this, the innovative oven features an accelerated curing process without sacrificing the durability and attractiveness of the final finish. This not only maximizes productivity but also minimizes energy consumption, promoting sustainable manufacturing practices within the industry.Furthermore, this breakthrough oven has been engineered to address the limitations of traditional coating processes. The technology enables an even application of the powder coating material, resulting in a flawless finish. Additionally, the oven is equipped with advanced safety features that protect the wheels from potential damage caused by overheating. This ensures that every product that emerges from the oven retains its structural integrity and meets the strictest quality control standards.By investing in this cutting-edge oven, wheel manufacturers and refinishing businesses can experience greater operational efficiency, cost-effectiveness, and increased customer satisfaction. The new oven's unrivaled performance and reliability make it an indispensable tool in the wheel manufacturing process, from initial production to refinishing and customization.The [company] constantly strives to provide its customers with state-of-the-art solutions to meet their evolving needs. In line with its commitment to innovation, the manufacturer offers comprehensive customer support services, including training programs and after-sales assistance. This ensures that clients can seamlessly integrate the oven into their existing manufacturing processes, allowing them to capitalize on its full potential.In conclusion, the introduction of this groundbreaking oven for powder coating wheels is set to redefine the automotive industry's standards for wheel manufacturing and refinishing. By successfully combining efficient curing processes, unparalleled reliability, and advanced safety features, the [company] demonstrates its leadership in providing cutting-edge solutions that pave the way for future advancements in the field. With this innovative oven, wheel manufacturers and refinishing businesses can confidently enhance their production capabilities, fulfilling the demands of discerning customers who value both performance and aesthetics.

Experience High-Quality Cross Draft Spray Booths for Your Painting Needs

Title: State-of-the-Art Cross Draft Spray Booth Revolutionizes Automotive Painting ProcessIntroduction:In an era where technological advancements continue to shape industries, the automotive industry is no exception. One such groundbreaking innovation is the state-of-the-art Cross Draft Spray Booth developed by an industry-leading company dedicated to revolutionizing automotive painting processes. This cutting-edge booth offers unrivaled efficiency, precision, and safety, setting a new industry standard for automotive manufacturers and painting professionals worldwide.Booth Efficiency and Versatility:The Cross Draft Spray Booth represents a game-changer in terms of efficiency due to its advanced technological features. The booth is designed to ensure optimal airflow, which eliminates contaminant particles that can interfere with the paintwork. Equipped with a high-performance air filtration system, it keeps the booth environment clean, resulting in flawless paint finishes.This innovative booth is also versatile, accommodating a wide range of vehicle sizes, from compact cars to large trucks. This flexibility allows manufacturers to maximize their painting capacity, streamline production, and reduce bottlenecks in the assembly line. With the possibility of customizing features and dimensions, the booth seamlessly integrates into any manufacturing facility.Precision and Consistency:Achieving precise and consistent paint finishes is crucial in the automotive industry. The Cross Draft Spray Booth utilizes advanced paint flow technology to ensure uniform coverage and color consistency on the car's surface. This cutting-edge technology guarantees superior product quality, enhancing the market appeal and customer satisfaction.Moreover, the booth's integrated computerized control system allows for adjustable temperature and humidity levels, providing optimal conditions for paint application. This precise environmental control, combined with proper air filtration, minimizes the risk of paint defects, ensuring a flawless paint finish every time.Enhanced Safety Features:Ensuring the safety of automotive painting professionals is of paramount importance. The Cross Draft Spray Booth incorporates a range of safety features designed to protect workers from harmful fumes and particles. The booth's advanced ventilation system efficiently evacuates harmful substances, maintaining a safe working environment.Additionally, the booth is equipped with cutting-edge fire suppression and detection mechanisms, reducing the risk of fire hazards during the painting process. This comprehensive safety infrastructure ensures the well-being of both workers and the manufacturing facility.Sustainable Manufacturing Practices:The Cross Draft Spray Booth also aligns with the growing global focus on sustainability. Through its energy-efficient design and intelligent system controls, the booth minimizes power consumption, reducing the overall carbon footprint of the manufacturing process. By adopting this innovative booth, manufacturers can promote environmentally friendly practices while improving efficiency and productivity.Conclusion:The development of the Cross Draft Spray Booth by {Company Name} represents a significant step forward for the automotive industry. This state-of-the-art innovation introduces unparalleled efficiency, precision, and safety to the painting process, ultimately enhancing the product quality and market competitiveness of automotive manufacturers. With its advanced features, this future-proof booth ensures uniform paint finishes, maximizes production capacity, and prioritizes worker safety. By embracing this sustainable and game-changing technology, automotive manufacturers worldwide can stay ahead of the curve, revolutionizing their painting processes for years to come.

Spray Booths for Various Applications: Cocoa Butter, Chocolate, Egg Wash, Airbrush Color, Petal Dust

Find the Best Handheld and Cordless Paint Sprayers for Your Next Project at PaintAccess Australia

: A Convenient and Efficient Way to PaintPainting can be a tedious and time-consuming task, especially if you're using traditional methods such as brushes and rollers. Fortunately, with the advancement of technology, there are now more efficient ways to paint, and one of them is by using a battery spray gun.A battery spray gun is a handheld device that sprays paint onto surfaces using a battery-powered motor. It's an efficient way to paint as it allows you to cover large areas quickly and evenly. Plus, you don't need to worry about getting your hands and clothes dirty as you would with traditional painting methods.If you're planning to purchase a battery spray gun, there are several factors to consider. Here are some of them:Type of Battery Spray GunThere are two types of battery spray guns: corded and cordless. Corded spray guns are plugged into an electrical outlet while cordless ones use a battery. Corded spray guns are more powerful than cordless ones, but cordless spray guns are more portable and convenient to use.Sprayer SizeThe size of the sprayer will determine how much paint it can hold, which will affect how long it can perform before needing a refill. If you're going to paint a large area, then choose a sprayer that holds more paint.Tip SizeThe tip size of the spray gun determines how much paint is released and the size of the spray pattern. Larger tip sizes are suitable for larger surfaces, while smaller tips are perfect for more delicate work.Paint TypeCheck if the spray gun is suitable for the type of paint you're using. Some sprayers are designed for thicker paints, while others are suited for thinner ones.BrandWhen it comes to reliable and high-quality battery spray guns, Graco is one of the leading brands in the market. They have a range of cordless and corded sprayers that suit different needs and sizes of projects.In conclusion, a battery spray gun is an efficient and convenient way to paint. It can save you time and effort while providing even coverage on surfaces. When buying a battery spray gun, consider the type of sprayer, sprayer size, tip size, paint type, and brand to ensure that you get the best value for your money. With PaintAccess.com.au, you'll find the best selection of handheld and cordless paint sprayers in Australia from authorized and reliable suppliers like Graco. Happy painting!

Efficient Spray Booth Sales and Services for Automotive, Aerospace and Industrial Applications

and Automotive Spray Booth.If you're in the automotive industry, having a high-quality spray booth is crucial to your success. A spray booth is a controlled environment designed to provide a clean, well-lit, and temperature-controlled space for painting vehicles. Without a proper spray booth, your final paint job could suffer, and your customers may not be satisfied with the work you're doing. That's where Eurotecno comes in.Eurotecno is a leading provider of spray booth sales and services, catering to a variety of industries including automotive, commercial vehicles, aerospace, and industrial sectors. One of their most popular products is the Infrared Spray Booth, which offers a range of advanced features and benefits.One major advantage of the Infrared Spray Booth is its efficiency. Unlike traditional spray booths, which rely on a combination of heat and airflow to cure the paint, an Infrared Spray Booth uses infrared technology to cure the paint more quickly and evenly. This means that vehicles can be painted and returned to the customer much faster, which is a major benefit for any busy auto body shop.In addition to its speed, the Infrared Spray Booth offers other benefits as well. For example, the booth comes equipped with a high-efficiency filtration system that traps airborne particles, ensuring a cleaner and safer working environment. This is particularly important in the automotive industry, where dust and debris can easily ruin a paint job.Furthermore, the Infrared Spray Booth is also highly customizable, meaning that businesses can tailor the booth to their specific needs. This is important because every auto body shop is different, and different vehicles require different types of painting and curing processes.Of course, the Infrared Spray Booth is just one of many high-quality spray booths available from Eurotecno. They also offer a range of other products, including Commercial Vehicle Spray Booths, Aerospace Spray Booths, and Industrial Spray Booths.Regardless of your industry or needs, Eurotecno has a spray booth solution that can help you achieve your goals. So if you're looking to upgrade your current spray booth or invest in a new one, be sure to check out Eurotecno and their wide range of options. With their expertise and dedication to quality, you can trust that you'll get an excellent product that will help your business thrive.

Professional Spray Booth Kit for Paint, Craft, and Hobby enthusiasts

article about the benefits and uses of a spray booth kit.IntroductionSpray booths are essential for anyone who is serious about paint craft, airbrushing, and other related hobbies. They are specifically designed to help prevent the inhalation of harmful fumes and particulates that are often generated when working with paints and other chemicals. However, simply having a spray booth is not enough. It needs to function properly and have the necessary features that make it efficient and effective. This is where the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products comes into play.FeaturesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is a complete kit that includes everything you need to set up your own spray booth. The most notable feature of this kit is the powerful fan that is included. The fan is designed to help remove harmful particles and fumes from the workspace quickly and efficiently. This helps to keep you safe while working and ensures that your finished products are of the highest quality.Another important feature of this kit is the fiberglass filter that is included. The filter effectively captures and removes harmful particles from the air, preventing them from being inhaled or settling on your finished work. This is a critical feature, particularly for those who work in enclosed spaces, as it helps to keep the air clean and breathable.BenefitsThere are many benefits to using a spray booth kit like the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products. For starters, it helps to keep the air in your workspace clean and breathable. This is crucial, as many paints and chemicals used in airbrushing and other related hobbies can be harmful when inhaled in large quantities. By removing these particles from the air, spray booth kits help to keep you safe while you work.Another benefit of using a spray booth kit is that it helps to improve the quality of your finished work. By removing particles from the air, your work is less likely to be marred by impurities and other blemishes. This can make a huge difference, particularly for those who are working on items that need to be sold or displayed publicly.Additionally, spray booth kits are often much more energy-efficient than other methods of ventilation. This is because they are designed to be highly efficient and effective, making it possible to use less electricity while still achieving the desired result.UsesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is ideal for a wide range of applications. It is particularly useful for those who work with airbrushes and spray paints, as these methods can generate a lot of harmful particulates and fumes. However, it can also be used for other types of crafts and hobbies that involve potentially harmful chemicals or materials.ConclusionIn conclusion, the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is an excellent choice for anyone who wants to work safely and effectively in their chosen craft or hobby. It is easy to set up, highly efficient, energy-saving, and provides a host of benefits that are hard to ignore. Whether you are an experienced professional or just starting out, this spray booth kit is definitely worth considering. So why wait? Order your New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products today and take your craft or hobby to the next level!

Get Portable and Convenient Spray Booth Solutions for Your Car" "Discover the Convenience of a Mobile Spray Booth for Your Vehicle

Title: Innovative Mobile Spray Booth Revolutionizes Automotive IndustryIntroduction:In today's fast-paced world, technological advancements have paved the way for numerous innovative solutions across various industries. One such groundbreaking invention making waves in the automotive sector is the revolutionary Mobile Spray Booth developed by an industry-leading company (brand name undisclosed). This cutting-edge mobile unit is poised to transform the way automotive refinishing is conducted, offering unparalleled convenience and efficiency to professionals in the field.[Insert General Overview of the Mobile Spray Booth]The Mobile Spray Booth offers a portable, self-contained solution for automotive refinishing that eliminates the need for a dedicated, fixed-location spray booth facility. Designed with ease of use and mobility in mind, this breakthrough technology offers professionals the freedom to operate in any location while delivering uncompromising quality results.1. Unparalleled Mobility and Versatility:The Mobile Spray Booth's compact design ensures easy transportation to various job sites, enabling automotive professionals to bring their refinishing services directly to customers. From large automotive repair shops to private garages, this innovative solution allows users to adapt to different environments seamlessly. The unit is equipped with a robust set of wheels and handles for effortless maneuverability and can be easily loaded onto a truck bed or trailer—a true game-changer for mobile automotive painters.2. Advanced Filtering and Ventilation Systems:Ensuring worker safety and environmental compliance are top priorities for any automotive spray booth. The Mobile Spray Booth integrates state-of-the-art ventilation and filtration systems, effectively capturing and containing overspray, chemical fumes, and volatile organic compounds (VOCs). This cutting-edge technology guarantees a clean and safe working environment, reducing health risks for professionals and minimizing the impact on the surrounding area.3. Energy Efficiency and Cost Savings:The Mobile Spray Booth is engineered with energy efficiency in mind. The unit utilizes innovative technologies to reduce energy consumption, resulting in substantial cost savings for automotive professionals. By eliminating the need for running expensive fixed-location spray booths continuously, the Mobile Spray Booth offers a significant advantage, improving profit margins and allowing businesses to invest in other essential areas.4. Full Compliance with Regulatory Standards:Adhering to strict regulatory standards is crucial for success in the automotive refinishing industry. The Mobile Spray Booth ensures compliance with all relevant safety, environmental, and industrial regulations, including ventilation requirements, filtration systems, and emissions management. This compliance guarantee provides peace of mind for professionals, allowing them to focus on delivering exceptional results.5. Streamlined Workflow and Enhanced Efficiency:The Mobile Spray Booth is designed to optimize workflow and operational efficiency. Its user-friendly features, such as integrated lighting systems, air hoses, and exhaust fans, facilitate a seamless and organized working environment. Moreover, the booth's advanced filters require minimal maintenance, reducing downtime and improving productivity.Conclusion:The advent of the Mobile Spray Booth marks a significant advancement in the automotive refinishing industry. Its portability, advanced filtration systems, energy efficiency, regulatory compliance, and streamlined workflow capabilities make it an indispensable tool for automotive professionals. This innovative solution not only saves time and money but also allows businesses to expand their services beyond traditional boundaries, catering to a wider range of customers. With the Mobile Spray Booth, the future of mobile automotive refinishing is transformed, setting new benchmarks for efficiency, convenience, and quality.

Enhancing Coating Techniques: Unraveling the Potential of Infrared Powder Coating

Title: Introducing Groundbreaking Infrared Powder Coating for Enhanced Efficiency and QualityIntroduction:Infrared Powder Coating, a pioneering technology developed by [Company Name], is revolutionizing the powder coating industry. By harnessing the power of infrared radiation, this innovative solution offers higher levels of efficiency, productivity, and quality. [Company Name] is proudly leading the way in this field, setting new standards and redefining the future of powder coating.Paragraph 1 (150 words):Powder coating has long been favored for its durability, eco-friendliness, and versatility. However, traditional powder coating methods have had their limitations when it comes to efficiency, requiring significant energy consumption and longer curing times. Recognizing this challenge, [Company Name] introduced Infrared Powder Coating as a game-changing solution.Infrared Powder Coating encompasses the use of advanced infrared radiation technology to optimize the curing process. Unlike traditional convection and radiant heating methods, infrared radiation directly heats the objects to be coated, resulting in faster and more uniform curing. This enables a substantial increase in production rates, reducing both energy consumption and production costs for businesses.Paragraph 2 (200 words):Underpinning the technological breakthrough of Infrared Powder Coating, [Company Name] has heavily invested in research and development, continuously enhancing the formulation of the powder material itself. The resulting powder formulation ensures compatibility with infrared radiation, enabling faster and more efficient curing while maintaining excellent adhesion and coating durability.A key advantage of Infrared Powder Coating is its ability to cure at lower temperatures. This not only saves energy but also reduces the risk of damage to heat-sensitive substrates. Furthermore, the precision control of the infrared radiation ensures full curing, eliminating the occurrence of undercured or overcured areas, which often leads to coating defects.By maximizing efficiency in the curing process, [Company Name]'s Infrared Powder Coating minimizes production time, enabling businesses to meet tight deadlines and increase overall capacity. Additionally, the reduction in energy consumption contributes to a greener workflow, aligning with sustainability goals and reducing the company's carbon footprint.Paragraph 3 (200 words):The benefits of Infrared Powder Coating are not limited to improved efficiency and reduced costs. The technology also enhances coating quality and consistency. The direct heating method of infrared radiation facilitates the effective flow and leveling of powder, resulting in smoother and more uniform coatings.Moreover, the precise temperature control offered by the infrared system allows for a broader range of coating applications, including heat-sensitive and delicate parts. [Company Name] ensures that their infrared systems are ergonomically designed, allowing easy integration into existing production lines and providing user-friendly operation features to streamline manufacturing processes.The versatility of Infrared Powder Coating extends to its applications across various industries, including automotive, consumer goods, electronics, and furniture. Putting customer satisfaction at the forefront, [Company Name] offers tailor-made solutions to meet the unique requirements of each industry, ensuring the achievement of impeccable finishes and long-lasting coatings.Conclusion (150 words):In conclusion, Infrared Powder Coating developed by [Company Name] represents a revolutionary advancement in the field of powder coating. By leveraging the power of infrared radiation technology, this innovative solution offers enhanced efficiency, reduced curing time, improved quality, and expanded application possibilities. Businesses can benefit from increased productivity, reduced energy consumption, and high-quality finishes that surpass traditional coating methods.As the industry leader, [Company Name] continues to push the boundaries of powder coating technology, contributing to a more sustainable and efficient manufacturing landscape. With their Infrared Powder Coating solutions, businesses can unlock new competitive advantages, achieve greater operational excellence, and deliver superior products to satisfy the demands of a dynamic market.

Discover the Ideal Powder Coating Oven for Wheels in the Latest News Content

Title: Cutting-Edge Powder Coating Oven for Wheels Revolutionizes the Automotive IndustryIntroduction:In a ground-breaking move that is set to revolutionize the automotive industry, a leading company has unveiled its latest innovation - a high-performance powder coating oven designed specifically for wheels. This cutting-edge technology is all set to transform the way wheel components are coated, enhancing their durability, appearance, and overall performance. With an unwavering commitment to excellence and a history of delivering top-notch products, this company is poised to disrupt the market with its state-of-the-art powder coating oven.The Features and Benefits of the Powder Coating Oven:The new powder coating oven boasts an array of features and benefits that position it at the forefront of wheel coating technology. With a focus on precision, efficiency, and cost-effectiveness, this innovative oven provides a wide range of advantages that surpass traditional coating methods.1. Advanced Temperature Control: The oven incorporates cutting-edge temperature control technology, ensuring precise and consistent heat distribution throughout the process. This results in a more even and superior coating quality, significantly reducing the risk of imperfections.2. Customization Options: The oven allows for a broad spectrum of color customization options. Manufacturers and vehicle owners can now choose from an extensive range of hues, finishes, and effects to match their unique preferences and brand identities. This flexibility opens up an entirely new realm of creative possibilities.3. Enhanced Durability: The oven's advanced powder coating process offers exceptional durability, surpassing traditional liquid paint applications. The coating adheres perfectly to the wheels, forming a robust protective layer that is highly resistant to scratches, chips, and corrosion caused by exposure to harsh conditions and road debris.4. Improved Environmental Sustainability: This groundbreaking technology boasts a significant environmental advantage over liquid paint alternatives. Powder coating generates minimal waste, eliminates harmful volatile organic compounds (VOCs), and consumes less energy, making it an eco-friendly choice for both manufacturers and consumers.5. Accelerated Production Process: The oven's high-speed curing capability drastically reduces production time, allowing manufacturers to efficiently meet increasing market demands. With shorter curing cycles and reduced cool-down phases, this cutting-edge technology vastly improves overall productivity.Company's Vision and Commitment to Quality:Driven by a commitment to delivering excellence, innovation, and customer satisfaction, the company behind this groundbreaking powder coating oven has established a strong reputation in the industry. Offering state-of-the-art solutions to meet ever-evolving industry demands, their unwavering commitment to quality has helped them stand out as a leader in the field.With decades of experience, the company's dedicated team of technicians, engineers, and designers have consistently pushed the boundaries of wheel coating technology. By striving for perfection and adopting a customer-centric approach, they have successfully developed this groundbreaking oven, poised to transform the automotive industry.Conclusion:Incorporating cutting-edge technology, high-performance features, and an unwavering commitment to quality, this advanced powder coating oven for wheels is set to revolutionize the automotive industry. With its ability to enhance durability, provide extensive customization, and minimize the environmental impact, this innovative solution is well-positioned to become the go-to choice for manufacturers and vehicle owners alike.As this pioneering oven hits the market, it is expected to drive new possibilities, set industry standards, and reshape traditional coating practices. With its immense potential to transform the way wheels are coated, this innovative technology marks a significant advancement in the automotive sector, delivering superior performance and aesthetics that transcend conventional methods.

Discover the Benefits of a Portable Spray Paint Booth for Hobbyists

Title: New Spray Paint Booth Revolutionizes the Hobby IndustryIntroduction:In an exciting development for hobbyists and enthusiasts, a cutting-edge spray paint booth has been launched by a prominent company in the industry. Designed to cater to the specific needs of artists, model-makers, and DIY enthusiasts, this innovative product aims to revolutionize hobby painting. With its advanced features and user-friendly design, this spray paint booth is set to make the process more efficient, enjoyable, and safer than ever before. [Company Name], a well-established manufacturer of high-quality hobby supplies and equipment, has unveiled their state-of-the-art spray paint booth. Drawing from their extensive expertise in the industry, the company has created a product that actively addresses common challenges faced by hobby painters. By understanding and catering to the needs of the hobby community, [Company Name] strives to enhance the painting experience for enthusiasts worldwide.Feature 1: Efficient and Protective DesignOne of the standout features of the new spray paint booth is its efficient design. The booth is specifically constructed to ensure that the paint particles remain contained within the unit, preventing contamination of the surrounding area. This not only provides a clean working environment but also reduces the risk of health hazards associated with toxic fumes. The booth's user-friendly design enables easy assembly and disassembly, making it convenient for use in various locations.Feature 2: Advanced Ventilation SystemTo further enhance safety and minimize the risk of respiratory issues, the spray paint booth is equipped with an advanced ventilation system. This system effectively captures and filters paint particles and fumes, ensuring a clean and breathable environment for the user. By expelling the fumes automatically, this innovative feature eliminates the need for additional exhaust fans or ventilation equipment.Feature 3: Adjustable Lighting and WorkspacePainting intricate details often requires adequate lighting, which is where the new spray paint booth truly shines. It comes equipped with an adjustable lighting system that provides optimal illumination for different projects. Additionally, the booth offers ample workspace to accommodate various sizes of models or artwork, ensuring maximum flexibility for hobbyists.Feature 4: Noise Reduction TechnologyRecognizing the importance of a peaceful and distraction-free environment, [Company Name] has incorporated noise reduction technology into the spray paint booth. This feature helps create a serene atmosphere, allowing hobbyists to concentrate on their projects without any disturbances. The reduced noise level significantly enhances the overall painting experience.Conclusion:The introduction of the new spray paint booth by [Company Name] is set to transform the hobby industry by making the painting process safer, more efficient, and enjoyable for enthusiasts across the globe. With a focus on addressing the specific needs of hobby painters, this cutting-edge equipment offers features such as efficient design, advanced ventilation, adjustable lighting, and noise reduction technology. As a result, artists, model-makers, and DIY enthusiasts can now expect an enhanced painting experience that promotes creativity while ensuring their health and safety.By investing in the latest technology and incorporating user feedback, [Company Name] continues to solidify its reputation as an industry leader. The release of this spray paint booth reaffirms their commitment to innovation and underscores their mission to empower hobbyists to create incredible works of art. Aspiring artists and enthusiasts can look forward to enhancing their craft with this revolutionary addition to the hobby market.