- Home

- Pretreatment and electrocoating process

Reliable Pretreatment and Electrocoating Process Manufacturer in China

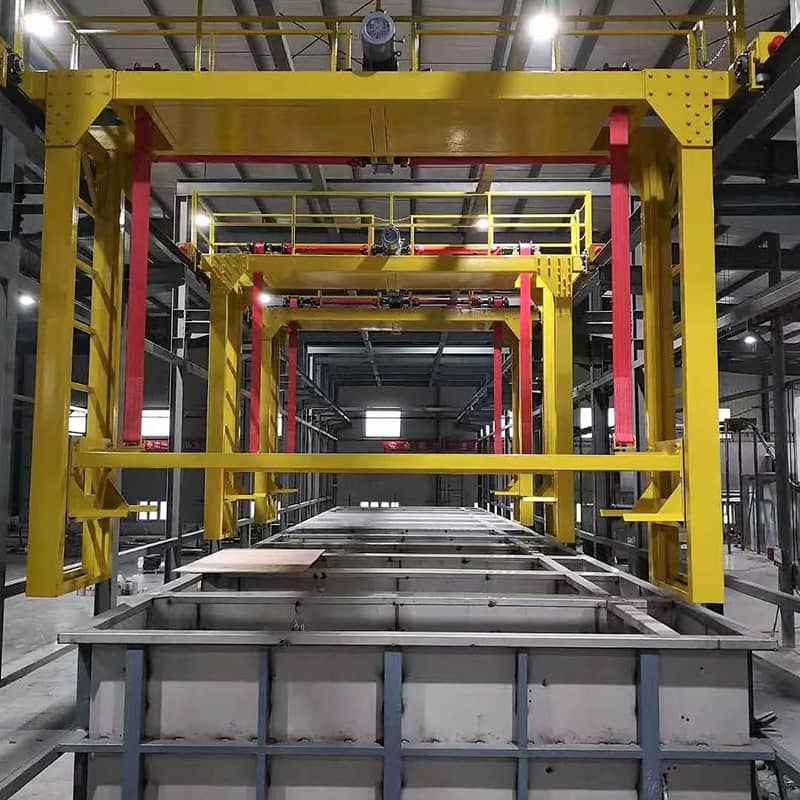

Our company is proud to introduce our top-of-the-line pretreatment and electrocoating processes for superior metal finishing. Our pretreatment process ensures optimal adhesion and corrosion resistance for all types of metal substrates, including aluminum, steel, and zinc. Our electrocoat process uses cutting-edge technology and advanced coatings to provide a durable and consistent finish that stands up to wear and tear.

Our pretreatment process involves a combination of cleaning, rinsing, and chemical treatment that prepares the metal surface for electrocoat application. Our electrocoat process utilizes an electrodeposition technique to create an even and uniform coat that retains its color and gloss over time. Additionally, our electrocoat process is eco-friendly and efficient, consuming less energy and producing less waste than traditional coating methods.

Whether for automotive, aerospace, or industrial applications, our pretreatment and electrocoating processes guarantee high-quality, reliable finishes that meet and exceed your expectations. Trust our company for your metal finishing needs and experience the benefits of our superior technology and expertise.

Jiangsu Suli Machinery Co., Ltd.

Company News

Related News

Pretreatment and electrocoating process

Looking for a reliable factory that offers pretreatment and electrocoating process services? Look no further! Our factory provides high-quality services to ensure the best results for your products. Contact us today!

- Efficient Pretreatment and Electrocoating Processes for OEMs - Reliable Supply from China

- Reviews

- Related Videos

Introducing our state-of-the-art pretreatment and electrocoating process for your high-performance coating needs. Designed to deliver exceptional corrosion resistance, adhesion, and durability, our process is perfect for a wide variety of applications in the automotive, aerospace, and industrial markets. Our pretreatment process includes a range of methods to ensure the proper preparation of your substrate, such as degreasing, cleaning, and phosphating. This level of attention to detail allows for excellent adhesion between the substrate and the coating, resulting in a more robust, long-lasting end product. Our electrocoating process utilizes advanced electrostatic technology to ensure every part is evenly coated for optimal coverage and protection against rust and other forms of corrosion. This process is highly efficient, cost-effective, and environmentally friendly, making it an ideal solution for both large-scale production runs and smaller custom orders. At our facility, we are committed to delivering the highest level of quality and precision in every step of our pretreatment and electrocoating process. We work closely with our clients to ensure that their specific needs are met, and every product is delivered on time and to their exact specifications. In short, if you are looking for reliable and exceptional quality pretreatment and electrocoating services, look no further than our team. Contact us today to learn more about how we can assist you in achieving your coating goals.

The pretreatment and electrocoating process is a game changer in the world of surface finishing. It provides high-quality coating and ensures durability. With this process, the surface is cleaned and prepared beforehand, so when the coating is applied, it does not peel off easily. The result is a smooth and even finish that looks great and lasts a long time. This process is highly recommended for any business that wants to stand out from its competitors. Overall, pretreatment and electrocoating process is an excellent investment for any business that prioritizes quality and longevity.

The pretreatment and electrocoating process is an excellent product that provides high-quality paint finish and durability for various metal substrates. The pretreatment process ensures proper surface preparation for the electrocoating process, which results in better adhesion of the paint and corrosion resistance. The electrocoating process provides a uniform and corrosion-resistant coating with excellent coverage. It is also an environmentally friendly and cost-effective process that reduces waste and energy consumption. Overall, the pretreatment and electrocoating process is an excellent investment for any metal coating application.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours