Top Suppliers of Various Spray Nozzles at Competitive Prices with OEM Services

By:Admin

Company News & Blog

High-Quality Small Powder Curing Ovens from Chinese Manufacturers and Suppliers

A small powdercoating oven is an essential piece of equipment for businesses and DIY enthusiasts who want to achieve long-lasting, high-quality finishes on their metal and plastic projects. These ovens are designed to cure powder coatings by baking them onto the surface of the substrate, creating a durable and attractive finish that resists wear, corrosion, fading, and chipping.At Hangzhou Color Powder Coating Equipment, we offer a range of small powdercoating ovens that are perfect for small-scale projects, such as automotive parts, motorcycle frames, bicycle components, jewelry, and DIY home improvement projects. Our ovens are made with high-quality materials and components, ensuring reliable performance, fast heat up times, and even temperature distribution throughout the curing process.One of the key advantages of using a small powdercoating oven is the ability to achieve a professional-grade finish without the need for expensive spray booths or specialized equipment. With a small oven, you can easily apply powder coatings using a spray gun or electrostatic method, and then cure them in the oven for a few minutes to achieve a hard, durable finish.Another advantage of a small powdercoating oven is its energy efficiency. These ovens are designed to minimize heat loss and maximize heat retention, which means that they consume less energy and require less time to heat up and cool down. This translates into significant cost savings over the long term, especially for DIY enthusiasts who use the oven frequently.When choosing a small powdercoating oven, it's important to consider a few key factors, such as the size of the oven, the type of heating element, the temperature range, and the ease of use. At Hangzhou Color Powder Coating Equipment, we offer a variety of small powdercoating ovens to suit different needs and budgets, from basic models with manual controls to advanced models with programmable digital interfaces.Overall, a small powdercoating oven is an excellent investment for anyone who wants to achieve professional-grade finishes on their metal and plastic projects. With its energy efficiency, durability, and ease of use, this equipment can help you take your DIY hobby or small business to the next level.

Hollow Cone Spray Patterns: Styles, Angles, Flow Rates, and More!

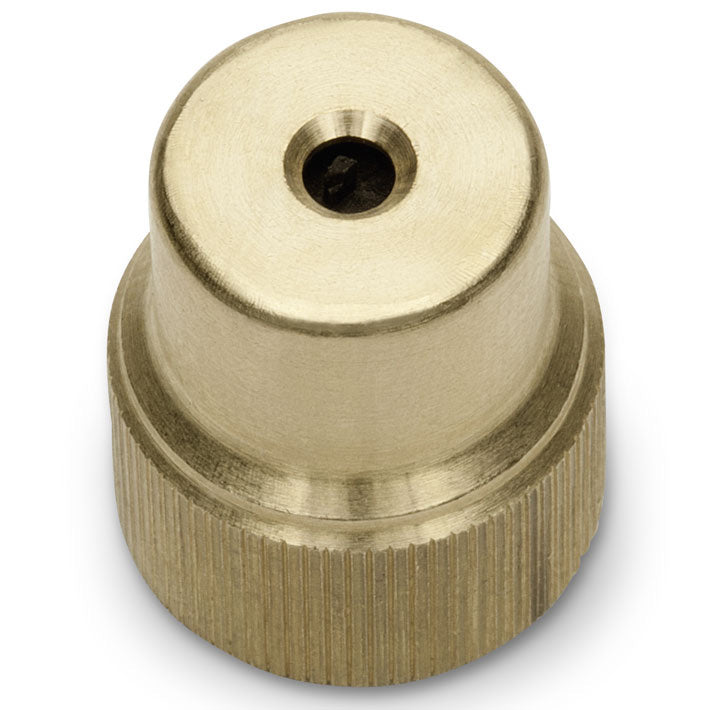

and Spraying Systems Co.Hollow Cone Spray Nozzle: A Comprehensive GuideSpray nozzles play a critical role in various industries such as agriculture, automotive, and manufacturing. They are used to distribute liquids, gases, and powders uniformly and accurately over a specific area. One of the common types of spray nozzles is the hollow cone spray nozzle.This type of spray nozzle produces a hollow cone pattern with a ring-shaped impact area. It is designed to create a fine mist, making it ideal for liquid distribution applications that require finer droplets. The hollow cone spray nozzle is widely used in industries such as papermaking, steel manufacturing, cooling, and dust suppression.Types of Hollow Cone Spray NozzlesHollow cone spray nozzles are available in various styles, spray angles, flow rates, and materials. The most common styles of hollow cone spray nozzles include:Standard: This is the most common type of hollow cone spray nozzle. It produces a hollow cone pattern with a standard spray angle ranging from 30 to 120 degrees. The standard hollow cone nozzle is used in applications such as cooling, dust suppression, and humidification.Narrow angle: The narrow-angle hollow cone spray nozzle produces a smaller diameter spray pattern than the standard hollow cone nozzle. The narrow-angle nozzle is ideal for applications that require a high-impact spray such as cleaning and surface treatment.Wide angle: The wide-angle hollow cone spray nozzle produces a larger diameter spray pattern than the standard hollow cone nozzle. The wide-angle nozzle is used in applications such as humidification and evaporative cooling.Full cone: The full cone hollow cone spray nozzle produces a full cone pattern with a solid impact area. The full cone nozzle is used in applications such as gas scrubbing and fire protection.Spray AnglesThe spray angle of a hollow cone spray nozzle refers to the angle of the cone created by the nozzle's orifice. Spray angles can be specified by degrees, which ranges from 30 to 120 degrees for standard hollow cone nozzles. Narrow-angle nozzles have a spray angle ranging from 15 to 30 degrees, while wide-angle nozzles have spray angles ranging from 120 to 180 degrees.Flow RatesThe flow rate of a spray nozzle refers to the amount of liquid or gas that it releases per minute. The flow rate of hollow cone spray nozzles varies depending on the size and style of the nozzle. Generally, flow rates for hollow cone spray nozzles range from 0.1 to 1000 gallons per minute (GPM) for liquid applications and 0.1 to 300 cubic feet per minute (CFM) for gas applications.MaterialsHollow cone spray nozzles are made of various materials such as brass, stainless steel, and plastics like nylon and PVC. The choice of material depends on the specific application and environment where the nozzle will be used. For example, brass is a good choice for applications where corrosive liquids are used, while stainless steel is ideal for high-temperature applications.Spraying Systems Co. Hollow Cone Spray NozzlesSpraying Systems Co. is a leading manufacturer of spray nozzles, including hollow cone spray nozzles. Their nozzles are made of high-quality materials and designed to meet the specific needs of various industries.Spraying Systems Co. offers a range of hollow cone spray nozzles with varying spray angles, flow rates, and materials. Their nozzles are suitable for various applications such as cooling, dust suppression, humidification, gas scrubbing, and fire protection.ConclusionHollow cone spray nozzles are a crucial component in various industrial applications. They are designed to produce a uniform and accurate distribution of liquids, gases, and powders. The choice of nozzle depends on the specific application, and factors such as spray angle, flow rate, and material are essential considerations.Spraying Systems Co. offers a range of high-quality hollow cone spray nozzles for various applications. Their nozzles are made of durable materials and designed to meet the specific needs of their customers. Whether you need a standard, narrow-angle, wide-angle, or full cone hollow cone spray nozzle, Spraying Systems Co. has got you covered.

Efficient and Large Spray Booths for Aerospace and Industrial Applications

AFC Finishing Systems, a leading manufacturer of spray booths and finishing equipment, has announced the launch of its new range of paint spray booths that are ideal for aerospace applications. These large-scale spray booths are designed to handle the complex needs of the aerospace industry, providing reliable and efficient solutions for all types of aircraft painting projects.With over four decades of experience in the finishing equipment industry, AFC Finishing Systems has become a trusted name in the market, providing innovative and cutting-edge products to its clients. The company is known for its commitment to quality, reliability, and customer satisfaction, ensuring that all products are built to the highest standards of safety and performance.The new range of paint spray booths is a testament to AFC Finishing Systems' dedication to meeting the needs of its customers. These booths are engineered to provide optimal airflow, temperature, and humidity control, ensuring that paint application is consistent and of the highest quality. They are also designed to be energy-efficient, reducing energy costs and environmental impact.In addition to aerospace applications, AFC Finishing Systems' paint spray booths are suitable for a wide range of industries, including automotive, marine, industrial, and woodworking. These booths are available in a range of sizes and configurations, allowing for customization to meet the specific needs of each client.One of the key benefits of AFC Finishing Systems' paint spray booths is their ease of use. They are designed to be simple and intuitive, requiring minimal training for operators. This ensures that projects are completed efficiently and effectively, with minimal downtime or errors.Another advantage of AFC Finishing Systems' paint spray booths is their durability. Built with high-quality materials and components, these booths are designed to withstand years of heavy use, providing long-lasting performance and reliability. They are also easy to maintain, with a range of service and support options available from the company.AFC Finishing Systems is committed to providing its clients with top-quality finishing equipment and services. With its new range of paint spray booths, the company is poised to further cement its position as a leading provider of innovative and reliable products for the aerospace and other industries.Overall, the new paint spray booths from AFC Finishing Systems provide a valuable solution for companies that require efficient and high-quality paint application for their products. With their advanced features, ease of use, and durability, these booths are an excellent investment for any business that requires high-quality finishing capabilities.For more information about AFC Finishing Systems and its new paint spray booths, visit the company's website or reach out to its team of experts for a consultation.

Choose the Best Plastic Flood Spray Nozzle for Industrial Applications

Spray Nozzles - The Best Solution for all Your Industrial NeedsIn any industrial application, the proper operation of a system depends on the use of the correct components. A crucial part of any industrial setup is the spray nozzle - it ensures that the flow of fluid is directed efficiently and effectively to ensure the required output. Spray nozzles also play a significant role in maintaining hygiene, safety and environmental regulations.When it comes to spray nozzles, Freudenberg FST is one of the most trusted and reliable brands in the market. In this blog, we will be discussing the Flat Fan Spray Nozzle provided by Freudenberg FST.Flat Fan Spray Nozzle - An OverviewAs the name suggests, a flat fan spray nozzle produces a flat fan-shaped pattern of liquid spray. It can be used for different purposes, such as washing, coating, cooling, and a lot more. Flat Fan Spray Nozzles are specially designed to meet the demands of different industrial applications, including spraying screens, conveyors, and more.Why Choose Freudenberg FST for Your Spray Nozzle Needs?Freudenberg FST is a well-known name in the field of spray nozzles. The company provides a wide range of spray nozzles made of different materials and sizes to cater to various industrial applications. When it comes to selecting a spray nozzle, the choice of material is a crucial consideration, and Freudenberg FST has an expert understanding of this.Freudenberg FST offers spray nozzles made from different materials, including plastic, stainless steel, and brass, to ensure maximum compatibility with the fluid being sprayed. One of the company's most popular spray nozzle is its plastic flood spray nozzle, which is a flat fan spray nozzle designed for a wide range of industrial applications.Plastic Flood Spray NozzlesThe plastic flood spray nozzle offered by Freudenberg FST is made of high-quality thermoplastic materials, ensuring excellent resistance to chemical corrosion and impacts. The plastic flood spray nozzle is also available in different sizes, ranging from 1/8" to 3/4", ensuring that it caters to different industrial applications.The plastic flood spray nozzle is ideally suited for applications where a wide fan-shaped spray is needed, such as cleaning walls, floors, and conveyors. The nozzle's spray angle can be adjusted to achieve the best performance, making it a versatile and suitable option for a wide range of applications.The Advantages of Choosing Freudenberg FST's Flat Fan Spray NozzleFreudenberg FST's flat fan spray nozzle offers many benefits, including:1. Wide angle of dispersionThe plastic flood spray nozzle provided by Freudenberg FST covers a wide angle of dispersion, making it ideal for industrial applications that require agile and efficient cleaning, cooling, and washing.2. Excellent durability and resistanceThe spray nozzle is made of top-quality thermoplastic material, which guarantees durability and resistance to impacts and chemical elements.3. Applicable to different flow ratesThe plastic flood spray nozzle is suitable for a wide range of industrial applications, thanks to its varying sizes, catering to different flow rates.4. VersatilityThe spray nozzle is versatile, meeting the needs of many different industrial applications, such as cleaning and washing conveyors, spraying screens, and solving numerous other operational challenges.ConclusionIn conclusion, spray nozzles are critical components in different industrial applications. Choosing the right spray nozzle for your industrial application is essential to ensure safety, hygiene, and efficient operation. The plastic flood spray nozzle offered by Freudenberg FST is an excellent choice for companies that need a solution for their industrial spraying needs.At Freudenberg FST, we offer a range of flat fan spray nozzles made from high-quality materials, with varying sizes to cater to different industrial applications. Our nozzles are designed to ensure optimal and efficient operation, and our team of experts is always available to help you make the right choice.So for all your spray nozzle needs, contact us today and let us help you find the best flat fan spray nozzle for your industrial application.

Build Your Own DIY Paint Spraying Booth in 9 Easy Steps

Building a DIY Paint Spraying Booth for a Safe and Clean WorkspaceWorking with aerosol cans, airbrushes, or high volume low pressure (HVLP) paint spraying systems requires a well-ventilated workspace to avoid inhaling fumes and overspray. Even if you wear a respirator, the risk of health hazards from toxic chemicals and particles cannot be completely eliminated. Besides, spraying paint in an open area can create a mess and ruin other surfaces that you don't intend to paint.That's where a homemade paint spraying booth comes in handy. By building a dedicated spray booth, you can contain the paint droplets and fumes in an enclosed space, capture them with a filter, and exhaust the air safely outside, leaving the surrounding area clean and free of contamination.Here are 9 steps to guide you through the process of building a basic paint spraying booth:1. Choose a locationFind a spot in your garage or workshop where you can fit the booth without blocking other objects or obstructing walkways. Ideally, the booth should be near an electrical outlet and a window or a vent to facilitate the exhaust.2. Measure and mark the size of the boothDecide how large you want the booth to be, based on the size of your workpieces and your available space. Use a tape measure and a straightedge to mark the outline of the booth on the floor. You can make it rectangular or square, but make sure it's at least 3 feet wide, 3 feet deep, and 6 feet tall to allow enough airflow and clearance.3. Frame the wallsUse 1x2 or 2x2 wooden studs to create the frame of the booth. Cut the studs to the lengths of your marked lines and assemble them using nails or screws. Make sure each corner forms a 90-degree angle and the frame is sturdy and level.4. Cover the walls with plastic sheetsAttach large sheets of clear plastic film or painter's plastic to the frame using staples or a staple gun. Make sure the plastic is taut and smooth, without any wrinkles or gaps. Leave one side open, which will be the entrance.5. Install a doorCut a slit in the plastic sheet for the entrance and attach a zipper or a flap to create a hinged doorway. Make sure it fits snugly and can be closed easily. You can also use magnets or velcro to secure the opening.6. Add lightingInstall a work light or a fluorescent tube light inside the booth to illuminate the work area. You can hang it from the ceiling or attach it to the frame. Make sure the light is bright enough and does not create shadows or glare.7. Insert a filter or exhaust fanTo remove the fumes and overspray from the booth, you can either use a filter or an exhaust fan. A filter is a mesh or fiber material that traps the particles and cleans the air, while an exhaust fan pulls the air out of the booth and directs it outside through a duct or a hose. You can choose either option depending on your budget and preference.8. Connect the exhaust to the window or ventIf you use an exhaust fan, connect the duct or hose to the window or vent that leads outside. You may need to drill a hole in the wall or use an adapter to fit the duct to the opening. Make sure the connection is tight and secure.9. Test and adjustBefore using the booth, turn on the fan or filter and spray some paint in the booth to see if it captures the overspray and fumes effectively. Adjust the position and power of the exhaust if necessary. Also, make sure to read the safety instructions of your paint system and wear appropriate protective gear such as gloves, goggles, and a respirator.By building a paint spraying booth, you not only protect yourself and your surroundings from harmful chemicals and mess but also increase the quality and consistency of your painting results. With a well-designed and functional booth, you can create a safe and clean workspace for your hobby or professional paint spraying needs.Keywords: paint spraying booth, DIY, aerosol cans, airbrush, HVLP system, fumes, overspray, respirator, toxic chemicals, particles, enclosed space, filter, exhaust, ventilation, plastic sheets, entrance, lighting, fluorescent tube, work area, fan, duct, safety.

How to Easily Mount a Blower onto a DIY Hobby Spray Booth

, Vent Works, Dayton Blower 6FHX9, fan mount panel, DIY project, ventilation, air quality, painting, hobby, woodworking, creativity.For DIY enthusiasts who enjoy painting and woodworking as a hobby, creating a spray booth is essential to ensure a proper working environment. Ventilation is crucial to maintain air quality, and a fan mount panel can help to achieve this goal. Vent Works has recently released a new DIY Hobby Spray Booth Fan Mount Panel, specially designed to fit the Dayton Blower 6FHX9.This fan mount panel is an excellent addition to any DIY project, allowing for easy installation and better control of ventilation. The panel is designed to be user-friendly, featuring all necessary mounting hardware and instructions. Users can easily attach it to the spray booth enclosure and connect it to the blower unit.The ventilation fan mount panel plays a critical role in maintaining air quality in a workspace. The device is particularly beneficial during painting or woodworking projects when dust and debris can quickly accumulate in the air. The use of a fan mount panel ensures that the air inside the booth is clean and healthy, making it safer and more comfortable to work in.By utilizing this innovative DIY Hobby Spray Booth Fan Mount Panel from Vent Works, hobbyists can enhance their creativity and enjoy their favorite pastime without worrying about air quality. So, whether you're a beginner or an experienced DIY enthusiast, this fan mount panel is a must-have for anyone looking to create and maintain a safe and healthy workspace.

Efficient Spray Booth Sales and Services for Automotive, Aerospace and Industrial Applications

and Automotive Spray Booth.If you're in the automotive industry, having a high-quality spray booth is crucial to your success. A spray booth is a controlled environment designed to provide a clean, well-lit, and temperature-controlled space for painting vehicles. Without a proper spray booth, your final paint job could suffer, and your customers may not be satisfied with the work you're doing. That's where Eurotecno comes in.Eurotecno is a leading provider of spray booth sales and services, catering to a variety of industries including automotive, commercial vehicles, aerospace, and industrial sectors. One of their most popular products is the Infrared Spray Booth, which offers a range of advanced features and benefits.One major advantage of the Infrared Spray Booth is its efficiency. Unlike traditional spray booths, which rely on a combination of heat and airflow to cure the paint, an Infrared Spray Booth uses infrared technology to cure the paint more quickly and evenly. This means that vehicles can be painted and returned to the customer much faster, which is a major benefit for any busy auto body shop.In addition to its speed, the Infrared Spray Booth offers other benefits as well. For example, the booth comes equipped with a high-efficiency filtration system that traps airborne particles, ensuring a cleaner and safer working environment. This is particularly important in the automotive industry, where dust and debris can easily ruin a paint job.Furthermore, the Infrared Spray Booth is also highly customizable, meaning that businesses can tailor the booth to their specific needs. This is important because every auto body shop is different, and different vehicles require different types of painting and curing processes.Of course, the Infrared Spray Booth is just one of many high-quality spray booths available from Eurotecno. They also offer a range of other products, including Commercial Vehicle Spray Booths, Aerospace Spray Booths, and Industrial Spray Booths.Regardless of your industry or needs, Eurotecno has a spray booth solution that can help you achieve your goals. So if you're looking to upgrade your current spray booth or invest in a new one, be sure to check out Eurotecno and their wide range of options. With their expertise and dedication to quality, you can trust that you'll get an excellent product that will help your business thrive.

Professional Spray Booth Kit for Paint, Craft, and Hobby enthusiasts

article about the benefits and uses of a spray booth kit.IntroductionSpray booths are essential for anyone who is serious about paint craft, airbrushing, and other related hobbies. They are specifically designed to help prevent the inhalation of harmful fumes and particulates that are often generated when working with paints and other chemicals. However, simply having a spray booth is not enough. It needs to function properly and have the necessary features that make it efficient and effective. This is where the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products comes into play.FeaturesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is a complete kit that includes everything you need to set up your own spray booth. The most notable feature of this kit is the powerful fan that is included. The fan is designed to help remove harmful particles and fumes from the workspace quickly and efficiently. This helps to keep you safe while working and ensures that your finished products are of the highest quality.Another important feature of this kit is the fiberglass filter that is included. The filter effectively captures and removes harmful particles from the air, preventing them from being inhaled or settling on your finished work. This is a critical feature, particularly for those who work in enclosed spaces, as it helps to keep the air clean and breathable.BenefitsThere are many benefits to using a spray booth kit like the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products. For starters, it helps to keep the air in your workspace clean and breathable. This is crucial, as many paints and chemicals used in airbrushing and other related hobbies can be harmful when inhaled in large quantities. By removing these particles from the air, spray booth kits help to keep you safe while you work.Another benefit of using a spray booth kit is that it helps to improve the quality of your finished work. By removing particles from the air, your work is less likely to be marred by impurities and other blemishes. This can make a huge difference, particularly for those who are working on items that need to be sold or displayed publicly.Additionally, spray booth kits are often much more energy-efficient than other methods of ventilation. This is because they are designed to be highly efficient and effective, making it possible to use less electricity while still achieving the desired result.UsesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is ideal for a wide range of applications. It is particularly useful for those who work with airbrushes and spray paints, as these methods can generate a lot of harmful particulates and fumes. However, it can also be used for other types of crafts and hobbies that involve potentially harmful chemicals or materials.ConclusionIn conclusion, the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is an excellent choice for anyone who wants to work safely and effectively in their chosen craft or hobby. It is easy to set up, highly efficient, energy-saving, and provides a host of benefits that are hard to ignore. Whether you are an experienced professional or just starting out, this spray booth kit is definitely worth considering. So why wait? Order your New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products today and take your craft or hobby to the next level!

Paint Fume Extraction Booth with Air Curtain Technology for Small to Medium-Scale Use

Booth Fume Extraction.If you own a business that involves painting or varnishing products, you need to be aware of the potential health hazards that come with these activities. In particular, the fumes produced during the painting process can be dangerous to the respiratory system, and can even cause cancer when inhaled over a long period of time. This is why it is important to invest in a good quality spray booth that can extract these fumes and provide a safe working environment for your employees. SMARTBooth from Vodex Ltd is one such product that can help you solve this problem with ease.SMARTBooth is a small to medium-sized paint booth that is designed to be used for most forms of spraying and varnishing. It features protective air curtain technology that reduces over-spray escape, which can help prevent contamination of the working area. Additionally, it features a fume extraction system that removes the harmful fumes generated during the painting process, thereby ensuring a safe and healthy working environment for your employees.One of the main advantages of using SMARTBooth is that it can help you comply with the relevant health and safety regulations. By investing in a good quality spray booth, you can demonstrate that you take the health and safety of your employees seriously, and this can help you avoid fines and legal problems associated with non-compliance.Another advantage of using SMARTBooth is that it can improve the quality of your products. By using a dedicated spray booth rather than spraying in an open environment, you can reduce the amount of contaminants that can affect the final finish of your products. This can result in a superior finish that is more uniform and consistent.When it comes to choosing a paint booth, it is important to consider factors such as the size of your operation, the types of products you work with, and your specific needs and requirements. SMARTBooth is a versatile product that can be customized to suit your specific needs. Whether you need a small booth for occasional use, or a larger booth for more frequent use, SMARTBooth can meet your needs.In conclusion, if you are looking for a high-quality paint booth that can help you achieve high-quality results while ensuring the health and safety of your employees, then consider investing in SMARTBooth from Vodex Ltd. With its advanced fume extraction system and protective air curtain technology, SMARTBooth offers a superior level of performance and protection, and can help you take your business to the next level. So why wait? Contact Vodex Ltd today and learn more about how SMARTBooth can benefit your business.

Inexpensive Powder Coating Oven Made from Old File Cabinet

DIY Powder Coat Oven Door Seal: A Vital Component in Your Powder Coating SetupPowder coating has quickly become a popular method of applying a durable and uniform finish to metal parts. While it is a relatively simple process, there are specific requirements that must be met to achieve the desired results. One crucial component of any successful powder coating setup is a high-quality oven to cure the powder-coated parts.Commercial powder coat ovens can be expensive, with prices ranging from a few thousand dollars up to tens of thousands of dollars. Fortunately, with a bit of ingenuity and a few basic tools, you can build your own DIY powder coating oven at a fraction of the cost.The key to building a successful oven is to source a suitable enclosure that can withstand high temperatures and provide good insulation. For many DIYers, an old file cabinet or discarded refrigerator can work well. The next step is to add insulation materials like fiberglass or ceramic fiber blankets to improve the oven’s heat retention capabilities.Once you have designed and built the perfect oven enclosure, it’s time to focus on the smaller components that will make or break your powder coating results. One such essential element is the oven door seal. In this blog, we will discuss the importance of a good oven door seal and guide you through the process of making one for your DIY powder coating oven.Why You Need an Oven Door SealThe main purpose of a door seal is to keep the heat trapped inside the oven. You need the heat to cure the powder-coated parts properly. An ill-fitting or worn door seal can allow heat to escape, leading to uneven curing and poorly coated parts.Additionally, having a good seal creates a controlled environment inside the oven, preventing outside contaminants such as dust and debris from entering the oven and adhering to the newly coated parts.How to Make Your Own Oven Door SealTo make your own DIY oven door seal, you will need a few basic tools and materials:- High-temperature silicone- A caulking gun- Masking tape- A sharp utility knifeHere are the steps to follow:Step 1: Measure the Dimensions of Your Oven DoorUse a tape measure to accurately determine the dimensions of your oven door. You will need this information to calculate the length of silicone sealant you need for the job.Step 2: Apply Masking Tape to the Oven Door FrameProtect the areas around the oven door by applying masking tape to the edges of the oven frame. This will prevent the silicone from sticking to areas where it is not needed.Step 3: Apply the Silicone SealantLoad the high-temperature silicone into the caulking gun and apply a thin bead of silicone around the perimeter of the oven door frame, ensuring that it forms a continuous seal. Pay extra attention to the corners and areas where the door typically leaks heat.Step 4: Smooth the Silicone SealantUse your finger or a plastic spatula to smooth out the silicone sealant, ensuring that it fills any gaps or inconsistencies in the oven door. Take your time and be thorough in this step as it can significantly impact the effectiveness of the finished door seal.Step 5: Allow the Silicone to CureFollow the manufacturer's instructions for curing the silicone sealant. Typically, a high-temperature silicone sealant will require at least 24 hours of curing time.Step 6: Test Your New Oven Door SealAfter the silicone sealant has cured, remove the masking tape and close the oven door. Test the seal by running your hand around the door frame and feeling for any escaping heat.A DIY oven door seal made of high-temperature silicone is a cost-effective solution to ensure optimal heat retention and a controlled environment inside your powder coating oven. With a little bit of effort and some handy tools, you can create an effective oven door seal that will help you achieve the best possible results from your powder coating process. In summary, when building a DIY powder coating oven, the oven door seal is a vital component that cannot be overlooked. By following our guide and using high-temperature silicone, you can create a sturdy and reliable oven door seal that will last for years to come.